In the active world of logistics, integrating Internet of Things (IoT) technology into warehouse management is important for enhancing efficiency, accuracy, and safety.

By utilizing connected devices and sensors, warehouses can achieve remarkable operational excellence.

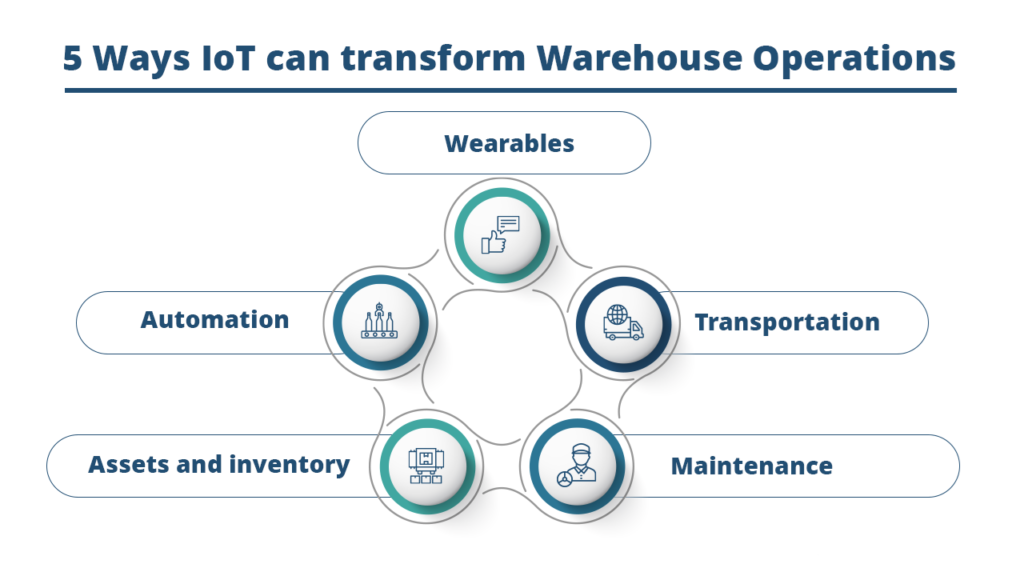

Here are five key strategies that highlight how IoT is revolutionizing warehouse operations:

1. Automation of Processes

IoT facilitates the automation of critical warehouse processes, optimizing efficiency and reducing human error. Robotic units equipped with IoT capabilities streamline order assembly and inventory management.

These devices collect and analyze large amounts of data on stock levels and warehouse performance, enabling employees to focus on higher-value tasks.

Case Study Insight: According to a report by Deloitte, warehouses that implemented IoT-driven automation observed a 25% improvement in order fulfillment accuracy and a 30% reduction in operational costs within the first year.

2. Enhanced Asset and Inventory Management

IoT transforms asset and inventory management by providing real-time visibility and control. Connected sensors monitor the movement of goods throughout the warehouse, while smart shelves equipped with IoT technology ensure precise inventory tracking and temperature monitoring.

Case Study Insight: A study by the Aberdeen Group shows that businesses using IoT for inventory management can reduce costs by 15% and increase inventory turnover by 10%. IoT also helps improve customer service by speeding up order fulfillment and making inventory data more accurate.

3. Improved Safety and Accountability

Safety is the most important thing in warehouse environments, and IoT improves workplace safety through real-time monitoring and proactive alerts.

Wearable IoT devices track employee activities and locations, promoting adherence to safety protocols and minimizing risks such as collisions and falls.

Case Study Insight: DHL reported a 40% reduction in workplace accidents following the implementation of IoT wearables across its warehouse facilities.

4. Optimized Transportation and Logistics

IoT-driven telematics and GPS technologies optimize transportation and logistics operations within warehouses. Vehicles equipped with IoT devices receive real-time updates on optimal routes and traffic conditions, enhancing delivery efficiency and reducing transportation costs.

Case Study Insight: FedEx experienced a 20% improvement in delivery efficiency and a 25% reduction in fuel consumption after integrating IoT into its logistics operations.

5. Predictive Maintenance

IoT sensors enable predictive maintenance by continuously monitoring equipment conditions and predicting potential failures. This proactive approach minimizes downtime, extends equipment lifespan, and reduces maintenance costs.

Case Study Insight: General Electric (GE) achieved a 35% decrease in maintenance costs and a 20% increase in equipment uptime through IoT-driven predictive maintenance strategies.

Conclusion

The integration of IoT into warehouse management represents a transformative shift toward enhanced operational efficiency, safety, and cost-effectiveness. By using IoT technologies, warehouses can optimize processes, improve inventory management, ensure workplace safety, streamline logistics, and achieve significant savings in operational costs.

As IoT solutions develop and become more accessible, the potential for innovation in smart warehousing continues to grow. Accepting these IoT-driven strategies allows warehouses to stay competitive in a rapidly changing market landscape while delivering superior service and reliability to their customers.

By adopting IoT technologies, warehouses not only future-proof their operations but also cover the way for continued growth and success in the digital age of logistics.